Glass containers:

• Glass is the preferred material for containers for injectable products.

• It is principally composed of silicon dioxide tetrahedron which is modified using oxides like sodium, potassium, calcium etc.

Types of glass:

- Type1: Highly resistant borosilicate glass

- Type2: Treated soda lime glass

- Type3: Soda lime glass

- Type4: General purpose glass

• Generally type1 glass is used for most of the sterile products.

• But type 2 and Type 3 glass can also be used when product has non aqueous vehicle.

• The protection of light sensitive drugs can be done by use of amber colored glass which is achieved by iron oxides.

• But iron oxides leach out in the product hence amber colored container should not be used in case of product which has iron catalyzed chemical.

• The glass should have sufficient mechanical strength to withstand high pressure during autoclaving and abuse during processing.

Sterile products made by glass:

Ampules:

• These are single dose containing formulations.

• Generally Type 1 glass is used.

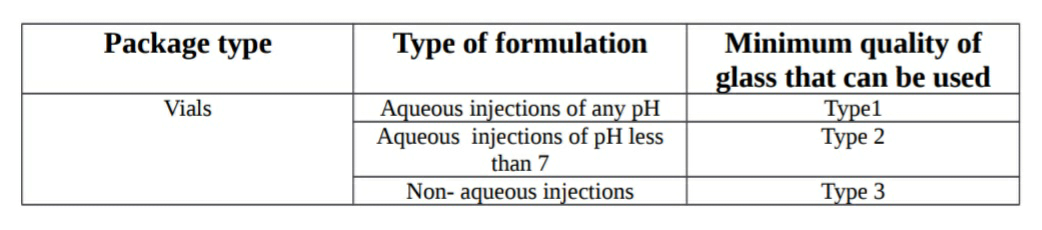

Vials:

These are used for multi dose parenteral products and provided with closure followed by aluminum seal to ensure the air tight packing.

Plastic containers:

Advantages:

• Light in weight

• Non breakable

• Has low toxicity

• Low reactivity with products

Disadvantages:

• Tissue toxicity can occur

• Reactivity due to sorption

• Leaching

Plastic is of two types:

Thermoplastic :

- Polyethylene

- LDPE (Low density polyethylene)

- HDPE (High density polyethylene)

- Polypropylene

- Polyvinyl chloride

- Polystyrene

- Polyamide (Nylon)

- Thermosets:

- Melamine

- Phenol formaldehyde

- Urea formaldehyde

• The two plastics have more interest in parenteral field that is polypropylene and copolymer polyethylene and polypropylene.

• Polypropylene is mostly used plastic because it has high tensile strength, high melting point (165°c) and low permeability to gases and water vapors.

Rubber:

• Rubber closures are mostly used to seal the opening of cartridges, vials, bottles and to provide soft and elastic permit to enter and withdrawn of a needle without loss of integrity of container.

• Principle unit of rubber closure is latex and vulcanizing agent, accelerator, activator, filler etc are added.

• Closures should be non- reactive with the product.

• Physical properties of rubber are elasticity, hardness, porosity.

• Sometimes plastic or lacquer coating is also done to rubber to prevent the sorption, vapor transfer and to provide complete barrier as desired.